![]() In the industrial landscape of California’s Central Valley, Stockton stands out as a vibrant hub of local metal fabrication. This versatile and essential manufacturing process involves shaping, cutting, and assembling metal materials to create various components and structures. It is employed across multiple industries, including construction, machinery, transportation, and more.

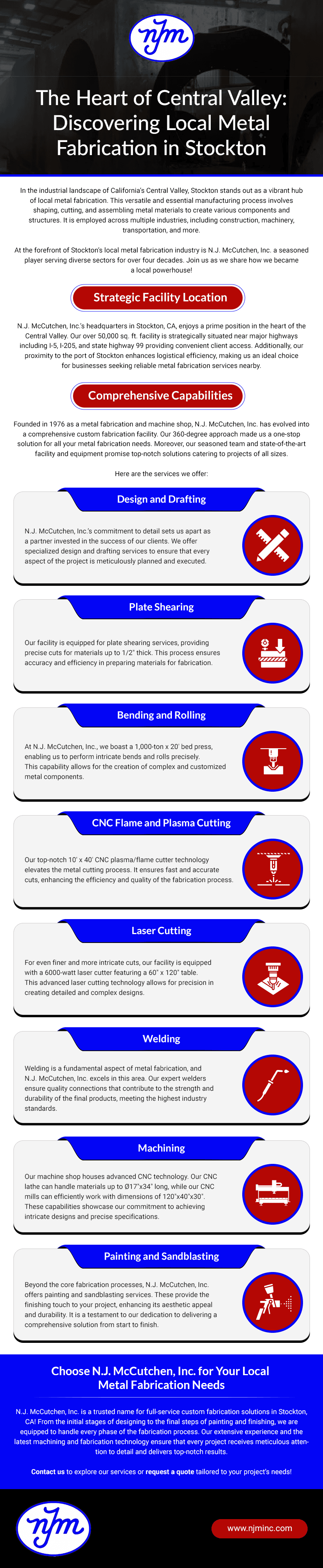

In the industrial landscape of California’s Central Valley, Stockton stands out as a vibrant hub of local metal fabrication. This versatile and essential manufacturing process involves shaping, cutting, and assembling metal materials to create various components and structures. It is employed across multiple industries, including construction, machinery, transportation, and more.

At the forefront of Stockton’s local metal fabrication industry is N.J. McCutchen, Inc. a seasoned player serving diverse sectors for over four decades. Join us as we share how we became a local powerhouse!

Strategic Facility Location

N.J. McCutchen, Inc.’s headquarters in Stockton, CA, enjoys a prime position in the heart of the Central Valley. Our over 50,000 sq. ft. facility is strategically situated near major highways including I-5, I-205, and state highway 99 providing convenient client access. Additionally, our proximity to the port of Stockton enhances logistical efficiency, making us an ideal choice for businesses seeking reliable metal fabrication services nearby.

Comprehensive Capabilities

Founded in 1976 as a metal fabrication and machine shop, N.J. McCutchen, Inc. has evolved into a comprehensive custom fabrication facility. Our 360-degree approach made us a one-stop solution for all your metal fabrication needs. Moreover, our seasoned team and state-of-the-art facility and equipment promise top-notch solutions catering to projects of all sizes.

Here are the services we offer:

Design and Drafting

N.J. McCutchen, Inc.’s commitment to detail sets us apart as a partner invested in the success of our clients. We offer specialized design and drafting services to ensure that every aspect of the project is meticulously planned and executed.

Plate Shearing

Our facility is equipped for plate shearing services, providing precise cuts for materials up to 1/2″ thick. This process ensures accuracy and efficiency in preparing materials for fabrication.

Bending and Rolling

At N.J. McCutchen, Inc., we boast a 1,000-ton x 20′ bed press, enabling us to perform intricate bends and rolls precisely. This capability allows for the creation of complex and customized metal components.

CNC Flame and Plasma Cutting

Our top-notch 10′ x 40′ CNC plasma/flame cutter technology elevates the metal cutting process. It ensures fast and accurate cuts, enhancing the efficiency and quality of the fabrication process.

Laser Cutting

For even finer and more intricate cuts, our facility is equipped with a 6000-watt laser cutter featuring a 60″ x 120″ table. This advanced laser cutting technology allows for precision in creating detailed and complex designs.

Welding

Welding is a fundamental aspect of metal fabrication, and N.J. McCutchen, Inc. excels in this area. Our expert welders ensure quality connections that contribute to the strength and durability of the final products, meeting the highest industry standards.

Machining

Our machine shop houses advanced CNC technology. Our CNC lathe can handle materials up to Ø17″x34″ long, while our CNC mills can efficiently work with dimensions of 120″x40″x30″. These capabilities showcase our commitment to achieving intricate designs and precise specifications.

Painting and Sandblasting

Beyond the core fabrication processes, N.J. McCutchen, Inc. offers painting and sandblasting services. These provide the finishing touch to your project, enhancing its aesthetic appeal and durability. It is a testament to our dedication to delivering a comprehensive solution from start to finish.

Choose N.J. McCutchen, Inc. for Your Local Metal Fabrication Needs

N.J. McCutchen, Inc. is a trusted name for full-service custom fabrication solutions in Stockton, CA! From the initial stages of designing to the final steps of painting and finishing, we are equipped to handle every phase of the fabrication process. Our extensive experience and the latest machining and fabrication technology ensure that every project receives meticulous attention to detail and delivers top-notch results.

Contact us to explore our services or request a quote tailored to your project’s needs!